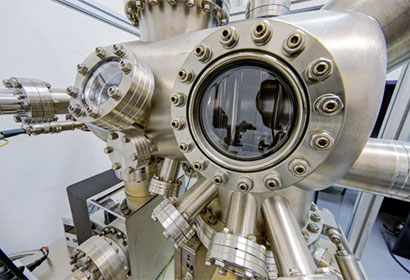

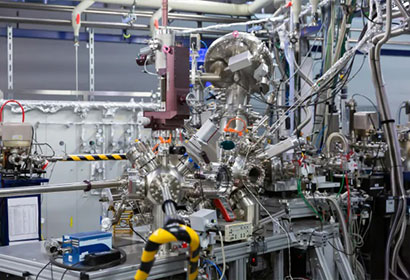

MTV specializes in supplying vacuum and ultra-high vacuum chambers for both industrial applications and Laboratory Research Centers. Our dedicated team of technical specialists provides comprehensive support throughout the entire realization process of the product, offering insights into cutting-edge construction technologies and materials to enhance production processes.

Key production stages, including cutting, bending, and metal processing, are all conducted in-house utilizing our state-of-the-art machinery, ensuring meticulous attention to detail and quality control.

We excel in in-house TIG and MIG welding services, working with carbon steel, stainless steel, and aluminum alloy materials. The quality of our welding services is paramount, with all operations executed according to third-party qualified procedures meticulously planned and managed by specialized professionals to meet specific customer requirements.

The integrity and tightness of welds in our chambers are rigorously verified through non-destructive tests such as Helium Leak Testing, X-Ray Inspection, Pressure Testing, and Ultrasonic Testing. Additionally, material tests and destructive tests are available upon request to further ensure the reliability and durability of our products.

Choose MTV for your vacuum chamber needs, and experience unparalleled expertise, precision, and quality every step of the way.