Vacuum Systems

MT VACUUM production and assembling of *Vacuum Chambers and Systems *Costumized Components for Pharma and Cosmetics

It takes time to build a corporate masterpiece, it takes time to build a life, and it takes time to develop and grow. So give yourself, your business, your family the time they deserve and the time they need.

Discover MoreVacuum Chambers & Systems

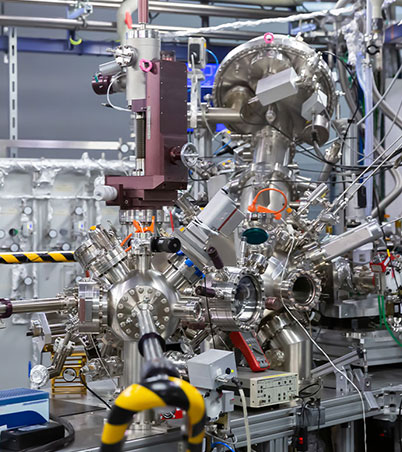

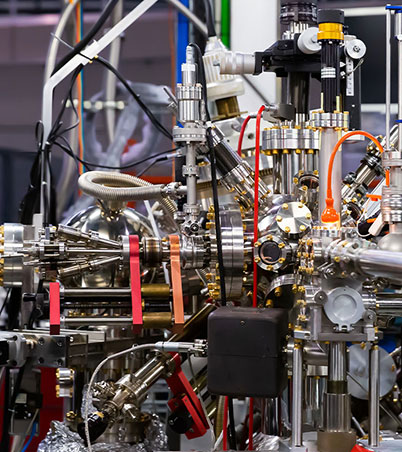

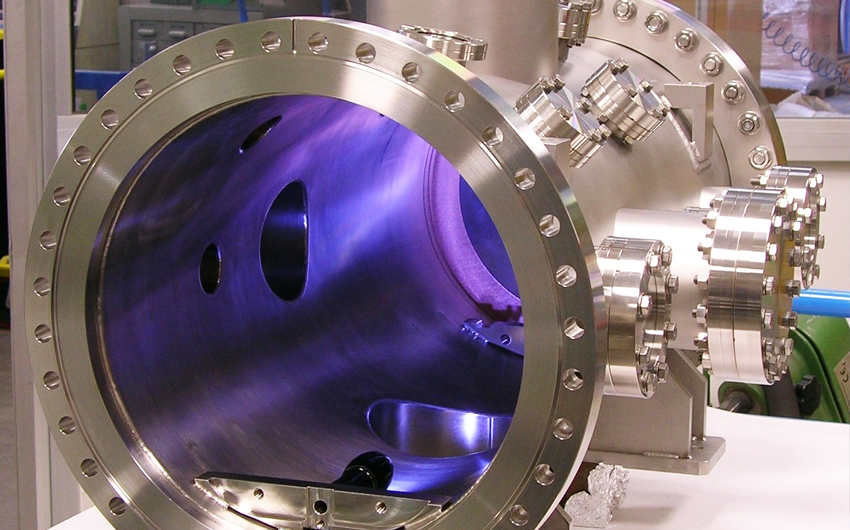

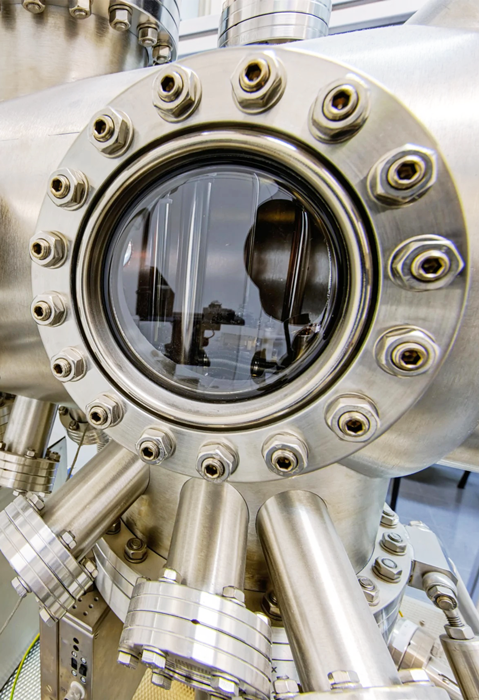

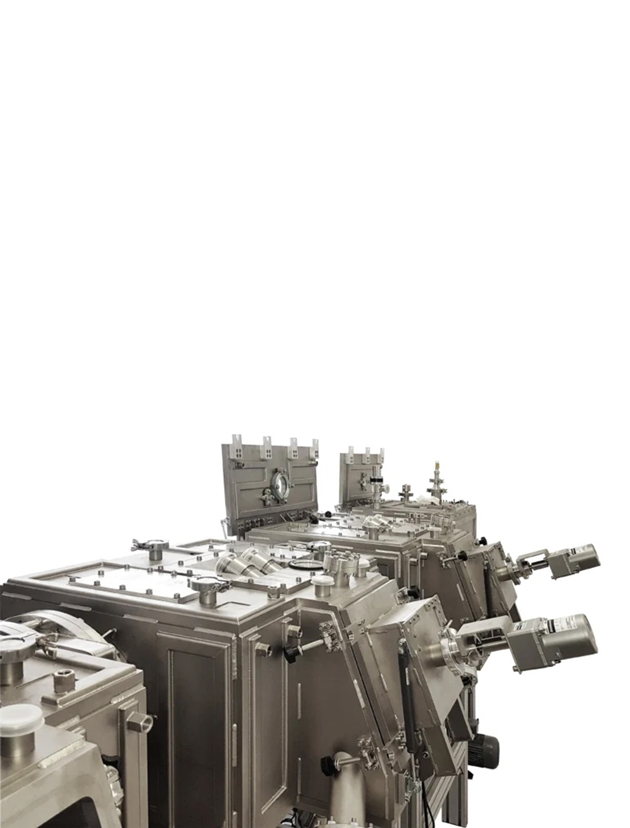

MT Vacuum designs and manufactures high-quality vacuum chambers and vacuum systems tailored to industrial and research applications, specializing in solutions for thin film deposition and ultra-high vacuum.

Learn morePrecision Mechanics

MT Vacuum excels in precision mechanics, offering top-tier components for vacuum vessels, deposition systems and precision components for Pharma and Cosmetics, ensuring reliability with state-of-the-art machinery.

Learn moreThin Film Deposition Systems

MT Vacuum produces advanced thin film deposition systems, providing full support from design to production to meet specific customer requirements.

Learn more

Company

Machinery and systems for industry and research centers

MTVacuum is a company born from the collaboration of companies and individuals operating in different industrial sectors with the aim of satisfying customers’ needs with competence, reliability and cost- effectiveness. Our mission is to support our partners from the design phase to the manufacture of components and vacuum machines for industry and Research Centers.

guarantee

quality

Design and production is carried out in-house by qualified technical staff and using state-of-the-art machinery

UH Vacuum chambers

Vacuum plants

Our customers also include leading Italian and European Laboratories and Research Centers for the supply of UH Vacuum chambers, Vacuum plants and systems, and precision mechanical components

Contact us

(+39) 0521 1415 285

Our Products

Our Projects

Our production includes

UHV Chambers and Systems

Precision Mechanical Components for Industry and Research Centers

Machines and Components for Industry

Pharma and Cosmetics Precision Components

MT Vacuum technology

Our state-of-the-art equipment includes laser cutting machines, TIG and Mig welding machines, metal cutting and forming machines. We perform dimensional checks in-house using five-axis 3D machines, roughness testers, profilometers and helium leak detectors. In cooperation we perform checks with 3D measurement Tool, laser measurement with Laser Tracker, magnetic permeability tests and material analysis.

To develop our customers’ designs and visualise product output before actual production, MTVacuum has the latest three-dimensional virtualisation and mechanical design software, based on CAD/CAM technology. The design of each component is carried out taking into account the required specifications, its final destination and the materials to be used, always in full compliance with the regulations governing the sector.

R&D

Prototype study and co-design

MTV offers customers constant support in the conception and development of their design ideas, providing expertise and professionalism at every stage of the study of the individual component and/or the complete machine.

All our technicians need is some basic information about the project (dimensions, overall dimensions, forces involved, etc.) to create models/prototypes that will then be developed through constant dialogue with the customer, thanks to the co-design method, so as to be sure of satisfying their every need.